Welcome, curious minds, to the colorful world of nylon granules! Today, we’re embarking on an exciting journey to explore the myriad types of nylon granules used in injection molding because we are a nylon granules manufacturer Delhi-based company. So, grab your magnifying glass, and let’s dive into this fascinating realm of polymers!

Understanding Nylon Granules: The Basics

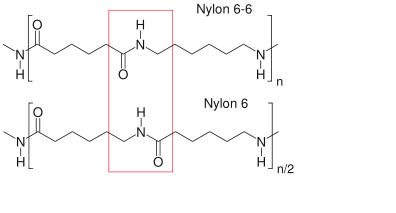

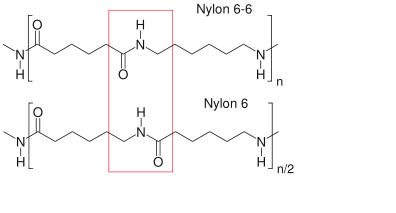

Ah, nylon – a versatile polymer that’s as fascinating as it is ubiquitous! But did you know that not all nylon granules are created equal? Indeed, there’s a wide array of nylon formulations tailored to suit different injection molding applications. From Nylon 6 to Nylon 66, each type boasts its own unique properties and characteristics.

Nylon 6: The Workhorse of Injection Molding

First up on our nylon granules tour is Nylon 6 – the tried-and-true workhorse of the injection molding world! Known for its excellent mechanical properties and versatility, Nylon 6 is a popular choice for a wide range of applications. From automotive components to consumer goods, this resilient polymer can handle it all with ease.

Nylon 66: Strength Meets Durability

Next, we have Nylon 66 – the heavyweight champion of the nylon granules family! Renowned for its superior strength and heat resistance, Nylon 66 is the go-to choice for applications requiring durability and reliability. Whether it’s high-stress automotive parts or industrial machinery components, Nylon 66 delivers unrivaled performance in the toughest conditions.

Nylon Blends: The Best of Both Worlds

But wait, there’s more! In addition to click here to learn more about Nylon 6 and Nylon 66, manufacturers also offer a variety of nylon blends that combine the best attributes of both polymers. These blends can be customized to achieve specific performance characteristics, such as enhanced impact resistance or improved chemical resistance. With nylon blends, the possibilities are endless!

Conclusion: A World of Possibilities with Nylon Granules

And there you have it, folks – a whirlwind tour of the diverse world of nylon granules for injection molding. Whether you’re in need of the strength and durability of Nylon 66 or the versatility of Nylon 6, there’s a nylon granule out there to suit your needs. So, the next time you’re embarking on an injection molding project, remember to choose your nylon granules wisely. After all, the right polymer can make all the difference in bringing your vision to life!

Demystifying Nylon Granules Properties for Injection Molding

Hey there, curious minds! Ever wondered what makes nylon granules tick? Well, you’re in for a treat because we’re about to dive deep into the fascinating world of nylon granules properties and how they can make or break your final product. So, grab your thinking caps, and let’s unravel this polymer puzzle together!

Strength and Durability: The Backbone of Nylon Granules

First up, let’s talk strength and durability – the bread and butter of nylon granules! One of the key properties of nylon granules is their exceptional tensile strength, which makes them ideal for applications requiring resilience and toughness. Whether it’s automotive parts, sporting equipment, or industrial components, nylon granules pack a punch when it comes to withstanding stress and impact.

Flexibility and Resilience: Bending Without Breaking

Next on our list of nylon granules properties is flexibility and resilience – the secret sauce behind their versatility. Unlike rigid materials that crack under pressure, nylon granules have a remarkable ability to bend and flex without losing their shape. This flexibility makes them perfect for applications that require parts to withstand bending, twisting, and vibration without succumbing to fatigue.

Chemical Resistance: Shielding Against Corrosive Forces

Last but not least, let’s talk chemical resistance – the unsung hero of nylon granules properties. One of the lesser-known advantages of nylon granules is their ability to resist degradation from exposure to chemicals, oils, and solvents. This makes them a preferred choice for applications in harsh environments where other materials may corrode or deteriorate over time.

Conclusion: Harnessing the Power of Nylon Granules Properties

And there you have it, folks – a crash course in understanding the properties of nylon granules and how they impact the final product. Whether it’s strength and durability, flexibility and resilience, or chemical resistance, nylon granules bring a host of benefits to the table for injection molding applications. So, the next time you’re embarking on a project, remember to consider the unique properties of nylon granules and how they can help you achieve your desired outcome. With the right polymer at your disposal, the possibilities are endless!

Navigating the Nylon Granules Manufacturing Maze in Delhi

Ahoy, fellow injection molding enthusiasts! So, you’re on the hunt for the perfect nylon granules manufacturer in Delhi, eh? Well, fear not, for I’ve got a treasure trove of tips to help you navigate the choppy waters of supplier selection. Sit tight and let’s set sail on this exciting adventure!

Assessing Quality and Reliability: The Foundation of a Solid Partnership

First things first, mateys – quality and reliability should be your North Star when choosing a nylon granules manufacturer in Delhi. Look for suppliers with a proven track record of delivering high-quality products consistently and on time. Check for certifications, conduct site visits if possible, and don’t be afraid to ask for references from satisfied customers. Remember, a reliable manufacturer is worth their weight in gold!

Transparency and Communication: Keeping the Lines Open

Ahoy, mateys! When it comes to selecting a nylon granules manufacturer in Delhi, communication is key! Look for suppliers who prioritize transparency and open lines of communication. A manufacturer who keeps you in the loop every step of the way – from order placement to delivery – is worth their weight in gold. So, hoist the sails and set a course for smooth sailing with a transparent partner by your side!

Cost Considerations: Balancing Quality with Affordability

Ahoy, me hearties! While quality should always be your top priority, don’t forget to keep an eye on the treasure chest – I mean, your budget! When selecting a nylon granules manufacturer in Delhi, consider the cost of their products and services carefully. Look for suppliers who offer competitive pricing without compromising on quality. Remember, a good deal is like finding buried treasure – it’s worth its weight in gold!

Conclusion: Charting a Course for Success with the Right Nylon Granules Manufacturer

Avast, ye scallywags! Choosing the right nylon granules manufacturer in Delhi may seem like navigating a treacherous sea, but with the right tips and tricks, you’ll soon be sailing towards success. Remember to prioritize quality and reliability, keep the lines of communication open, and weigh cost considerations carefully. With a trusted manufacturer by your side, you’ll be well on your way to injection molding greatness. So, hoist the Jolly Roger and set sail for smooth seas ahead!

Riding the Wave of Material Innovation in Delhi’s Nylon Granules Industry

Ahoy, adventurers of the injection molding realm! Prepare to embark on a thrilling journey through the ever-evolving landscape of material innovation and sustainable alternatives to traditional nylon granules in Delhi. Join me as we uncover the latest trends and groundbreaking developments shaping the future of polymer production!

Bioplastics: Nature’s Bounty in the World of Injection Molding

First up on our expedition is the exciting world of bioplastics – Mother Nature’s gift to the polymer universe! Bioplastics, derived from renewable sources such as corn starch, sugarcane, or even algae, offer a sustainable alternative to traditional nylon granules. With their biodegradable properties and reduced environmental footprint, bioplastics are gaining traction as eco-friendly options for injection molding applications in Delhi’s bustling manufacturing scene.

Recycled Nylon Granules: Turning Trash into Treasure

Avast, me hearties! Next on our quest for sustainable alternatives is the treasure trove of recycled nylon granules. By harnessing the power of recycling, manufacturers in Delhi are transforming discarded materials into valuable resources for injection molding. Recycled nylon granules not only reduce waste and conserve natural resources but also offer cost savings and environmental benefits. It’s a win-win situation for both pirates and planet alike!

Bio-based Nylon: A Leap Towards Greener Pastures

Hoist the sails, adventurers! Our final stop on this voyage of discovery brings us to the promising realm of bio-based nylon – a beacon of hope for a greener, more sustainable future. Bio-based nylon, derived from renewable sources such as castor oil or bioethanol, offers a renewable alternative to traditional petroleum-based nylon granules. With its reduced carbon footprint and lower environmental impact, bio-based nylon is paving the way for a more sustainable injection molding industry in Delhi and beyond.

Conclusion: Charting a Course Towards Sustainable Seas with Delhi’s Nylon Granules Industry

Ahoy, fellow adventurers! As we conclude our expedition through the trends in material innovation and sustainable alternatives to traditional nylon granules in Delhi, one thing becomes abundantly clear – the winds of change are blowing in favor of sustainability and environmental stewardship. Whether it’s through the adoption of bioplastics, recycled nylon granules, or bio-based nylon, manufacturers in Delhi are charting a course towards greener pastures and a brighter future for injection molding. So, hoist the flag of sustainability high and set sail towards a more eco-friendly tomorrow!