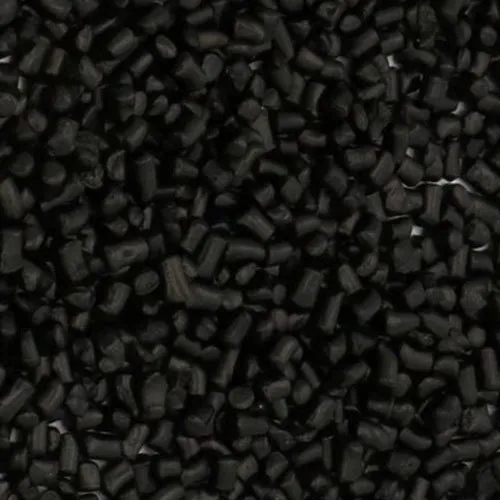

Nylon 6 glass filled Plastic Granules

Nylon 6 glass filled Plastic Granules are a versatile and widely used engineering plastic material known for their exceptional strength, durability, and thermal properties. At Aarvi Polymers, we specialize in manufacturing and supplying high-quality nylon granules that meet the specific requirements of various industries.

| Property | Details |

|---|---|

| Material | Nylon 6 |

| Usage/Application | Plastic Moulding |

| Color | Black |

| Density | 1.32 g/cm3 |

| Melting Point | 214 Degree Celsius |

| Form | Granules |

Aarvi Polymers takes monstrous pleasure in its role as a pioneering force in the polymer industry. With a constant recognition on innovation and sustainability, we specialize inside the production of top class-grade nylon granules, inclusive of the relatively sought-after Nylon 6 glass-crammed variation. Through modern-day generation and unwavering dedication to excellence, we deliver granules that redefine power, versatility, and overall performance throughout numerous applications

Understanding Nylon 6 glass filled Plastic Granules:

Nylon 6 glass filled Plastic Granules, strengthened with glass fibers, represents a class of engineering thermoplastics recognised for their exquisite energy, stiffness, and dimensional balance. This specialised variation of nylon reveals substantial use in industries requiring sturdy substances capable of withstanding harsh working situations and disturbing environments. From automotive components and electric enclosures to industrial machinery and customer goods, Nylon 6 glass-crammed granules provide exceptional sturdiness and reliability.

The Granulation Process:

At Aarvi Polymers, precision and exceptional are at the coronary heart of our granulation system. We begin by using cautiously selecting top rate-grade Nylon 6 resin and incorporating top notch glass fibers to reap the desired mechanical residences. Our modern centers characteristic advanced extrusion and compounding equipment, allowing us to precisely manipulate the dispersion of glass fibers inside the polymer matrix.

During extrusion, the molten resin undergoes thorough mixing and homogenization to make certain uniform distribution of glass fibers, optimizing strength and stiffness whilst preserving first rate drift characteristics. The extruded strands are then pelletized into granules of steady size and form, go through stringent exceptional control measures to uphold our uncompromising standards.

Quality Assurance and Performance Testing:

At Aarvi Polymers, best warranty is embedded in each element of our operations. Our devoted team of specialists conducts comprehensive performance trying out to validate the mechanical residences and integrity of Nylon 6 glass filled Plastic Granules. Through advanced checking out methodologies, which include tensile strength, flexural modulus, and effect resistance exams, we ensure that our granules meet or exceed the maximum stringent industry standards.

Furthermore, we leverage advanced analytical strategies, which include scanning electron microscopy (SEM) and thermal evaluation, to evaluate the microstructure and thermal behavior of our granules. These rigorous trying out protocols allow us to deliver granules that continually outperform expectancies, imparting our customers with a competitive facet of their respective markets.

Custom Solutions and Technical Expertise:

Recognizing the various desires of our customers, we offer customizable solutions tailored to specific software necessities. Whether it’s enhancing the structural integrity of automobile components or enhancing the performance of electrical insulators, our crew of experienced engineers collaborates carefully with clients to expand tailor-made formulations and offer technical support during the product lifecycle.

Moreover, we remain steadfast in our dedication to sustainability and environmental stewardship. By optimizing resource usage and minimizing waste generation, we try to reduce our ecological footprint and make contributions to a greater sustainable future for generations to come back.

Conclusion:

Aarvi Polymers stands as a beacon of innovation and excellence inside the polymer enterprise, driven by using a continuing pursuit of first-rate, overall performance, and purchaser pride. Our Nylon 6 glass-crammed granules epitomize strength, versatility, and reliability, empowering our clients to push the limits of what’s possible in their respective fields.

As we hold to innovate and evolve, we stay steadfast in our commitment to excellence and sustainability, striving to exceed expectancies and set new benchmarks for excellence. At Aarvi Polymers, we envision a destiny wherein strength meets versatility, where innovation thrives, and in which partnerships flourish. Together, we form a world of limitless opportunities, one granule at a time.